![]() The theme is "Materials for Space Quality"

The theme is "Materials for Space Quality"

An inside story of SAMPE Japan 2023

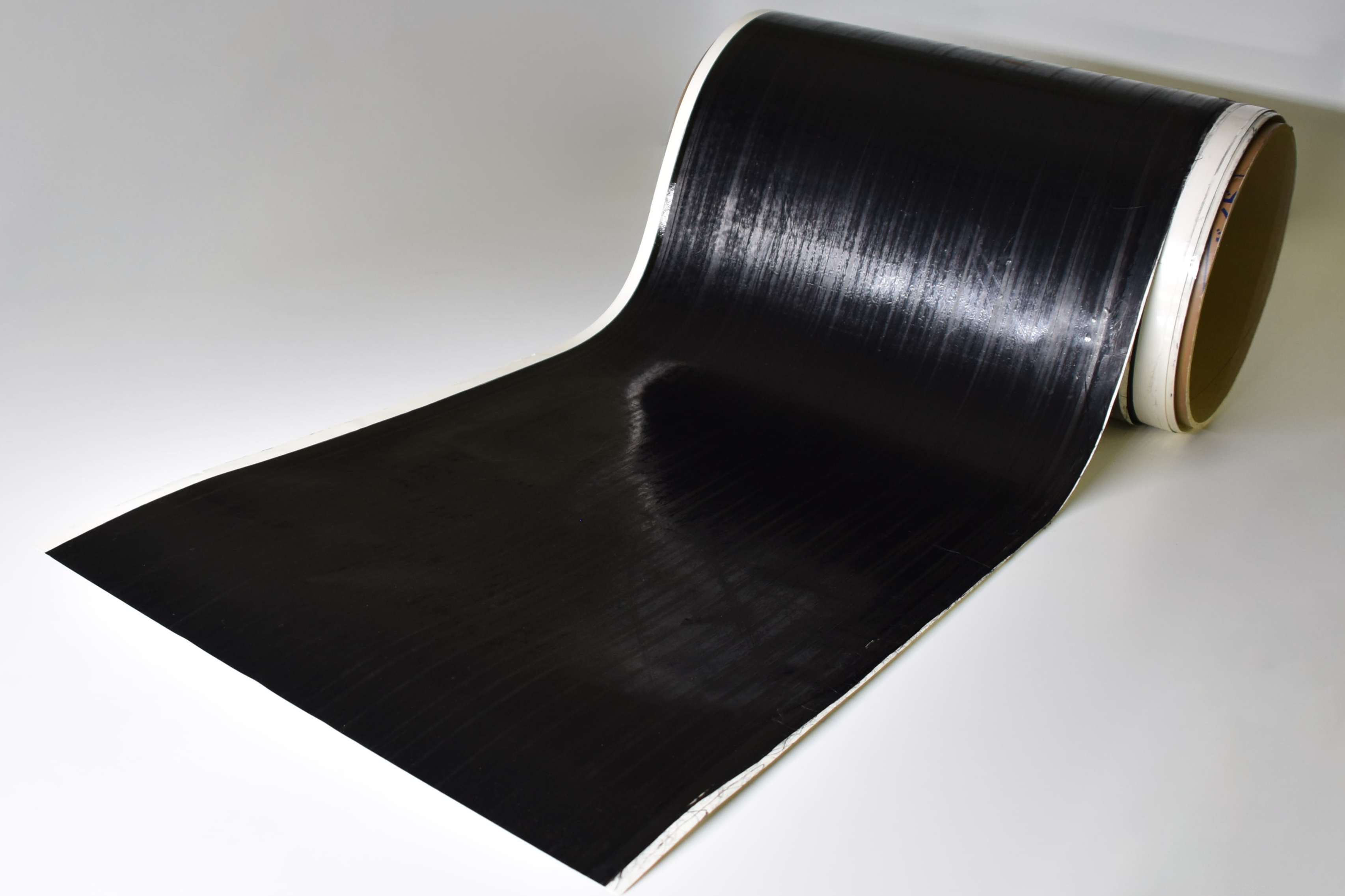

As announced in press releases, CARBON FLY has developed "CNT Hybrid Prepreg" in collaboration with Japan U-pica.co.ltd. Prepreg is a strip-shaped composite material used as an intermediate material for molded products. By using our CNT film and Nippon U-Pica's resin [CBZ], we have achieved lighter weight, higher strength, and higher productivity compared to metal and carbon fiber. In fact, components manufactured using this prepreg were delivered to a university nano-satellite project, where they passed the prescribed vibration and shock tests after being made lighter.

We have chosen "SAMPE Japan Advanced Materials Technology Exhibition 2023" (held at Tokyo Big Sight from November 29 (Wed.) to December 1 (Fri.), 2023), where people interested in carbon materials and other new materials gather, as the place to unveil this prepreg.

We believe that this prepreg can be used for all kinds of molded products such as mobility, sporting goods, construction materials, and other future lightweight products. However, this was the first time it was unveiled. Having actually passed vibration and shock tests for satellite applications, we decided to focus on the fact that this material can withstand harsh environments such as space.

And the theme chosen was "Materials for Space Quality.

Since we were exhibiting jointly with Japan Yupica this time, we dared to hide the colors of the two companies, and aimed to create a booth that reminded us of outer space with this theme throughout.

First, we used our original orbital elevator visual as an eye-catcher in a large scale. This design itself was created because CNT is said to be the only material that can realize tethers (cables) for orbital elevators, but we also added the logo of Yupika Japan in the hope that prepreg will allow it to be used for the structure of stations and climbers. We made it a special specification.

In order to design the entire booth in the image of outer space, the panels were also rounded to resemble a planet, rather than the usual rectangular shape.

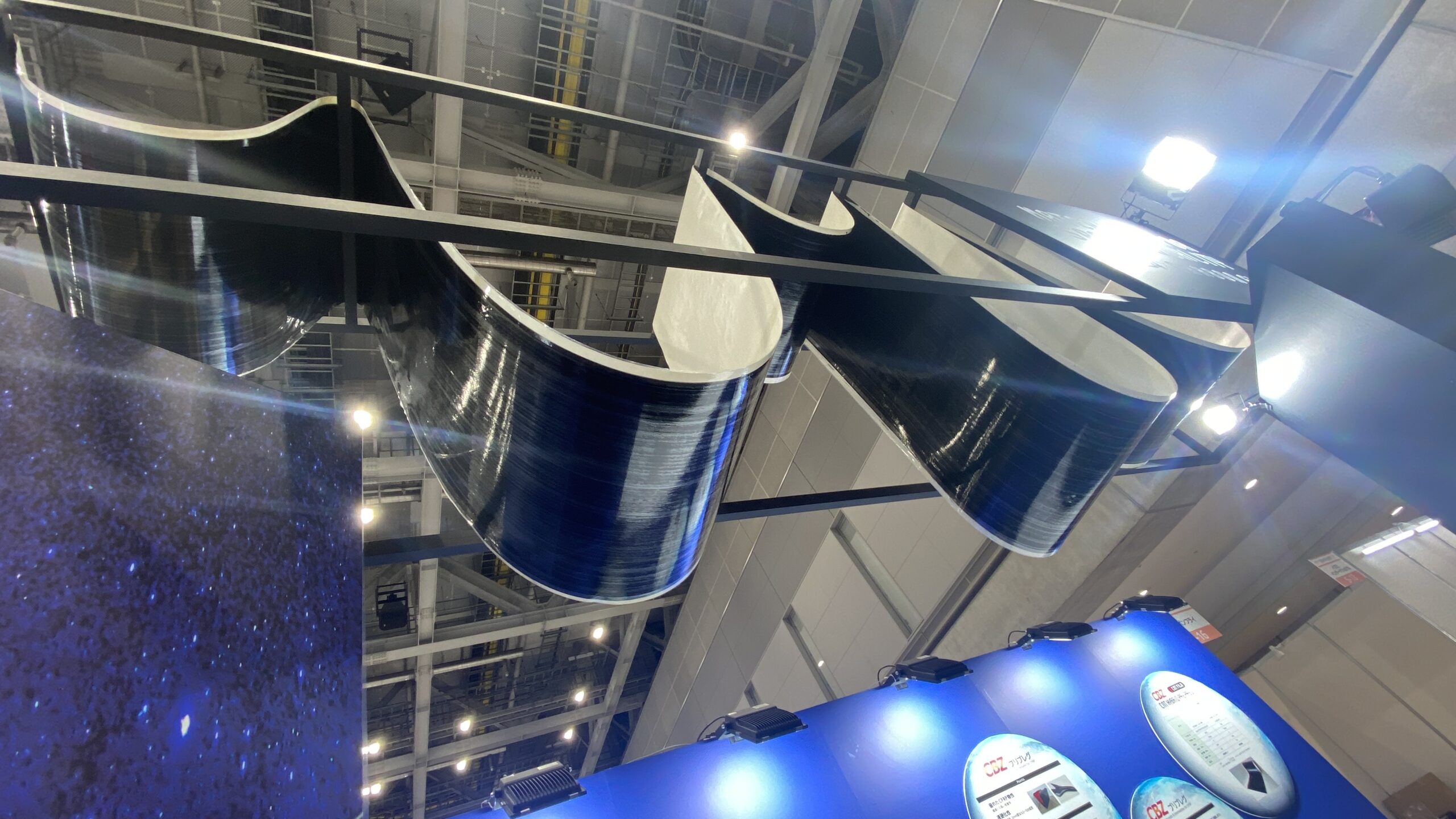

Expression of long length on the top sign

One of the reasons why CNT prepreg has not been distributed yet is that only a limited number of companies can produce high-quality CNTs that can be made into films using only CNTs, and mass production is difficult. Our company has now produced 100m. How should we communicate this big step forward? We wanted to showcase the continuity and suppleness of this material more prominently, rather than just displaying it as it is rolled, as is the case with carbon fiber prepreg!

So we decided to display the prepreg draped over the upper sign. The installation company cooperated with us on this challenging order to drape the product itself rather than the ornaments. We had the frame assembled in advance, and the day before the exhibition, we were on site to install the sign.

Unlike cloth, the material has a bouncy feel and a backing, so we had to actually drape it to see how it would look, but we were relieved to find that it draped more beautifully than we had imagined.

This made it possible to explain to customers during the exhibition that "all this length of CNT film is made of CNT film," while pointing upward. They were impressed to see how far we have come in the production of CNT film, looking up at the prepreg.

CNT hybrid prepreg has become a product that we can present with confidence. We were able to produce this well in our booth, and as a result, we were awarded the Excellent Exhibit Award.

We believe in the power of creativity, where details have meaning, and will continue to transmit (push forward) our message.